FlashIO – IoT Kit

A plug and play IoT kit for immediate deployments and connect to multiple data sources like PLCs, SCADA, DCS systems. Visualize the process data or machine data within few seconds. The IoT Kit includes PLC Drivers, OPC Clients, Remote Monitoring Application, Real Time Alerts & Notifications, Trends, User Management, KPIs Dashboarding.

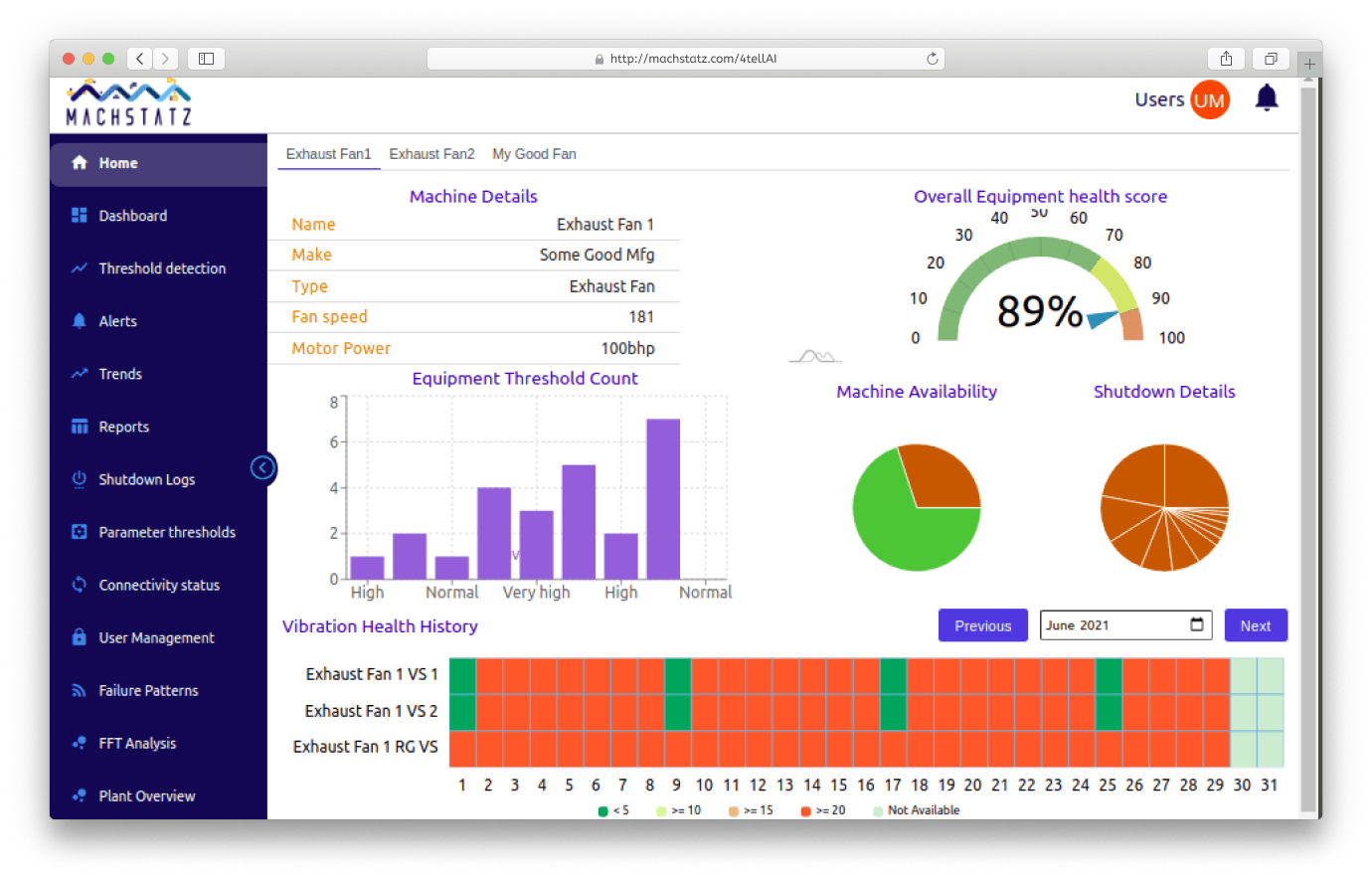

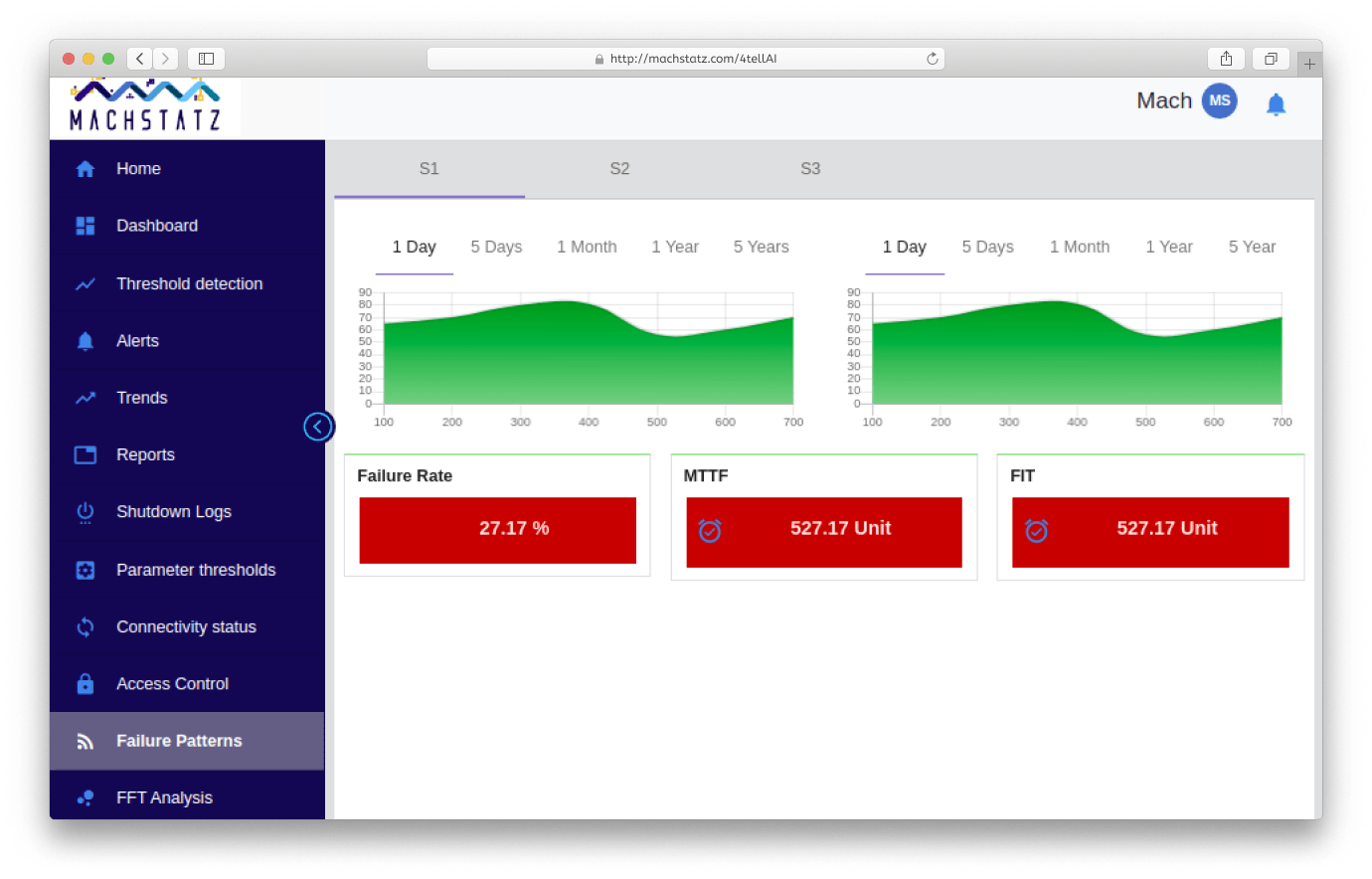

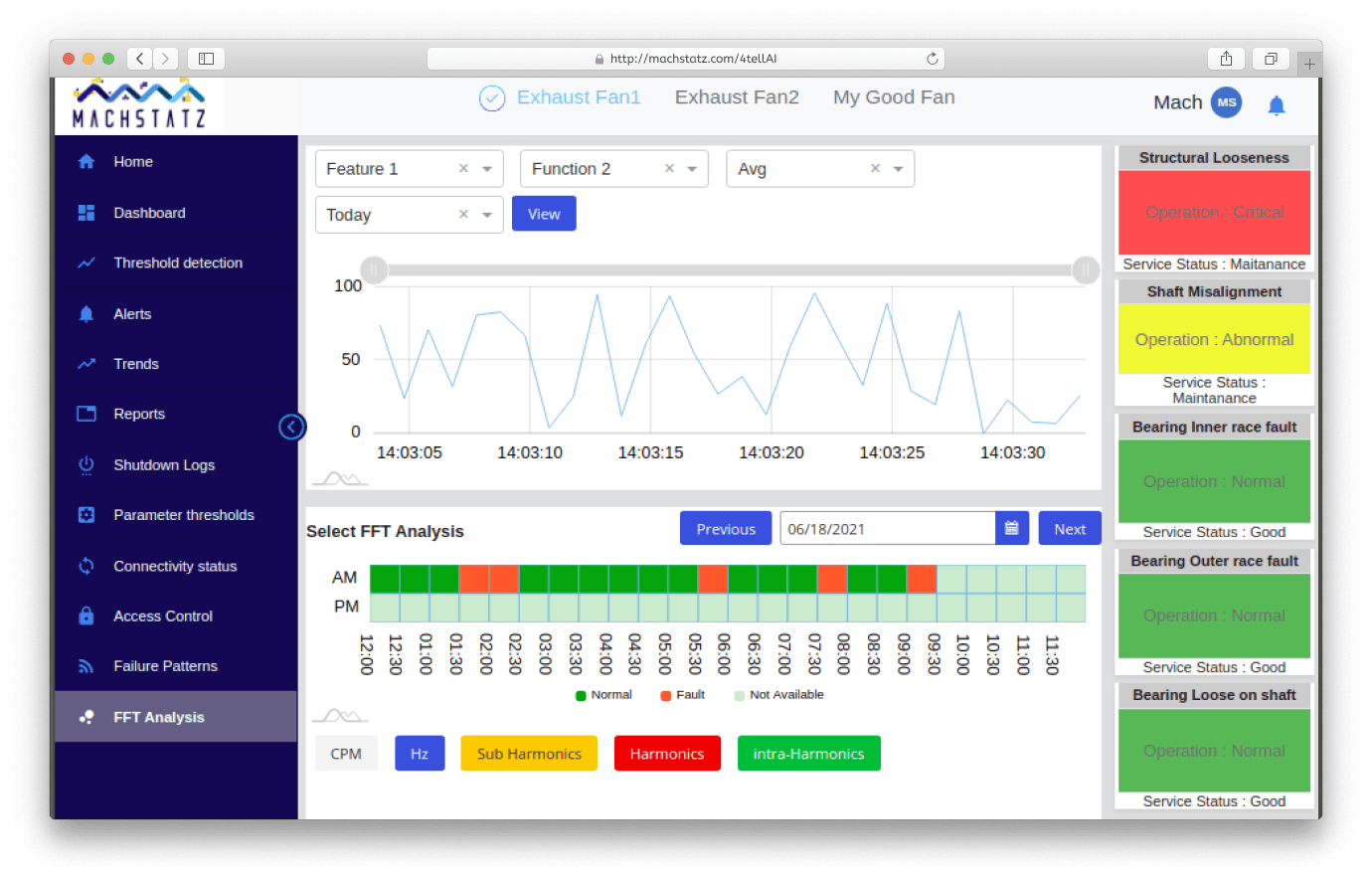

Learn more4TellAI – Condition Based Monitoring

Untimely machine breakdowns are costly - both financially as well as in terms of reputation. You don’t want that. 4tellai allows you to avoid such unpleasant scenarios by automatically identifying critical issues with your machines.

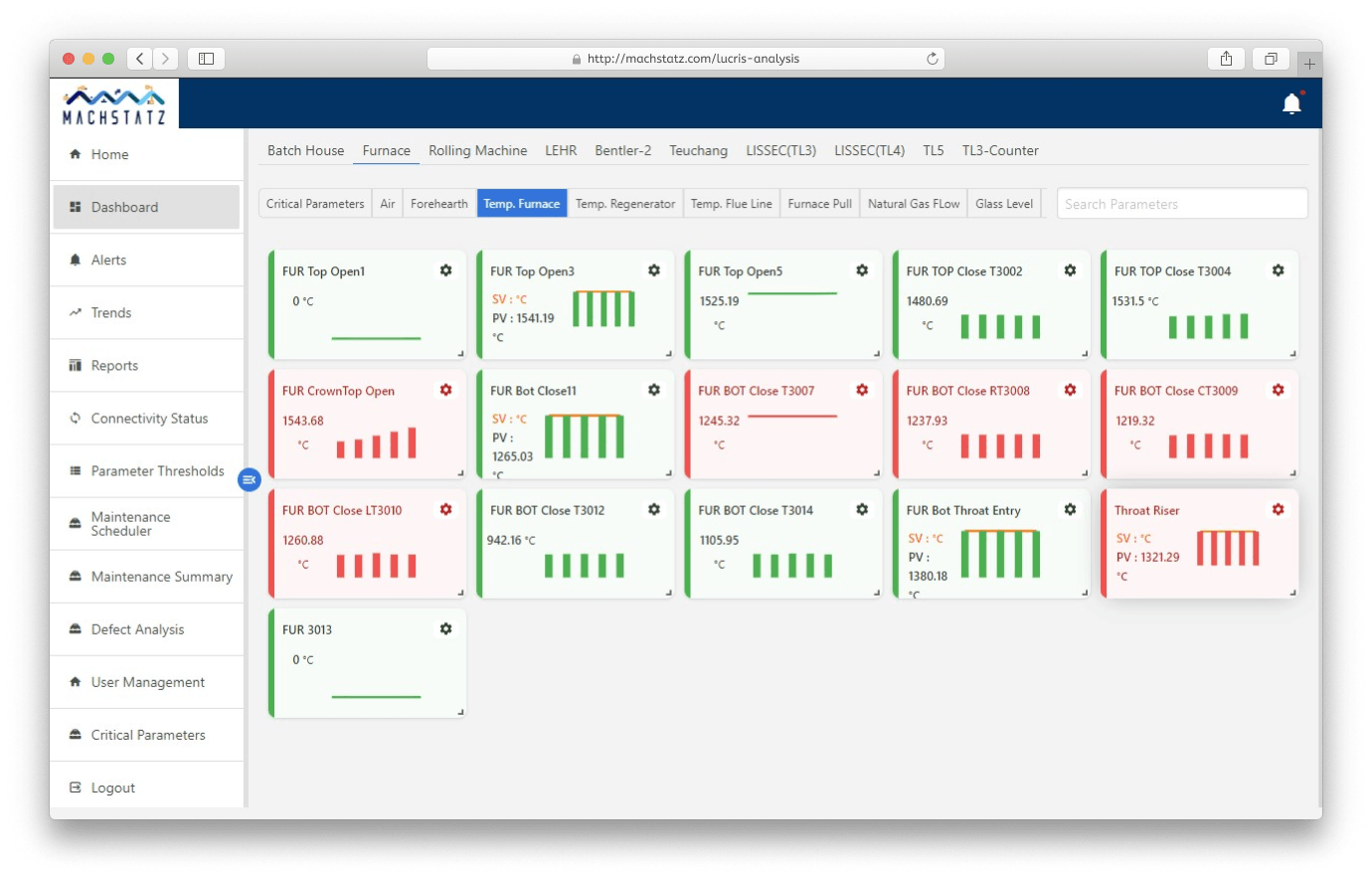

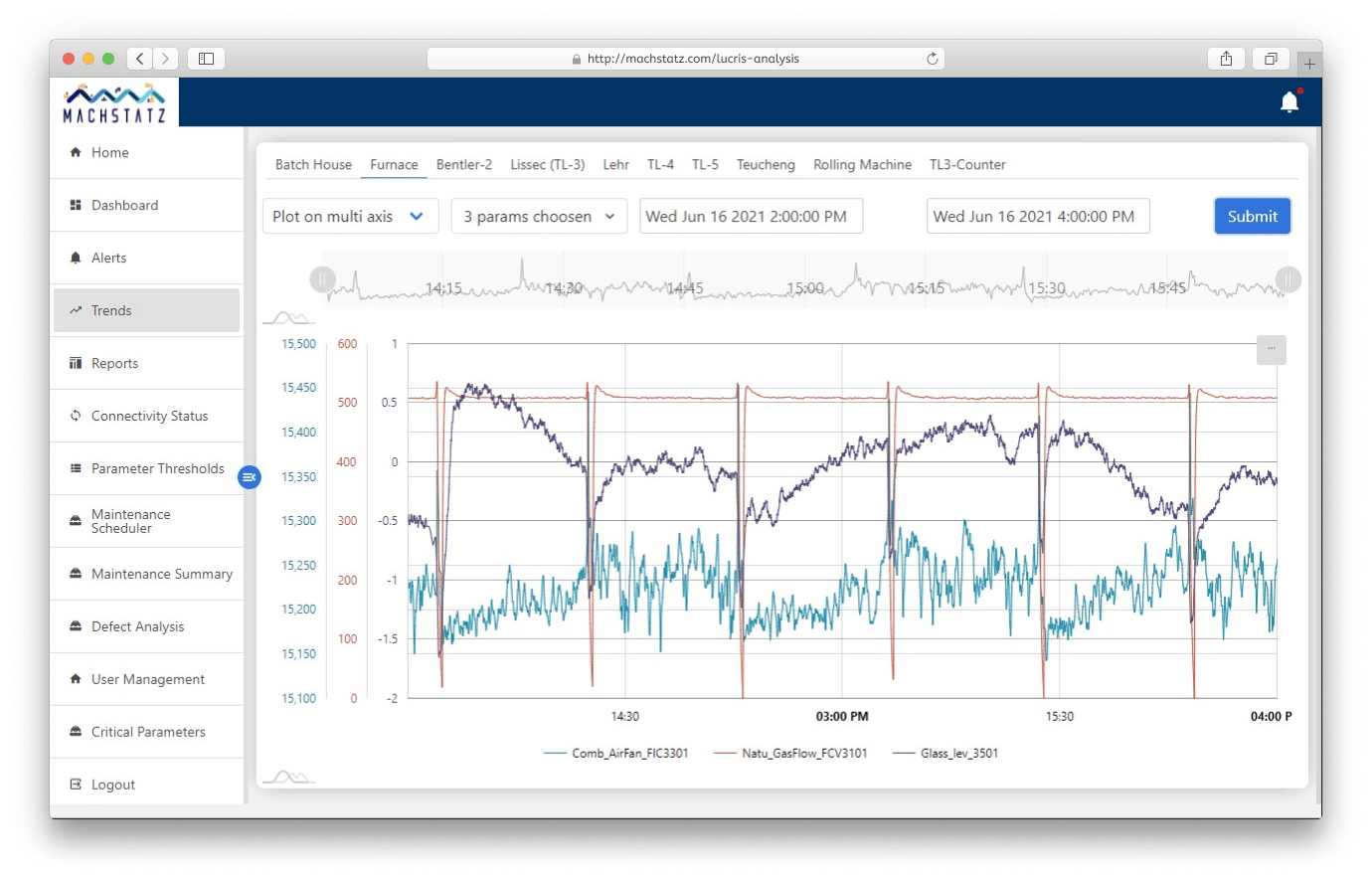

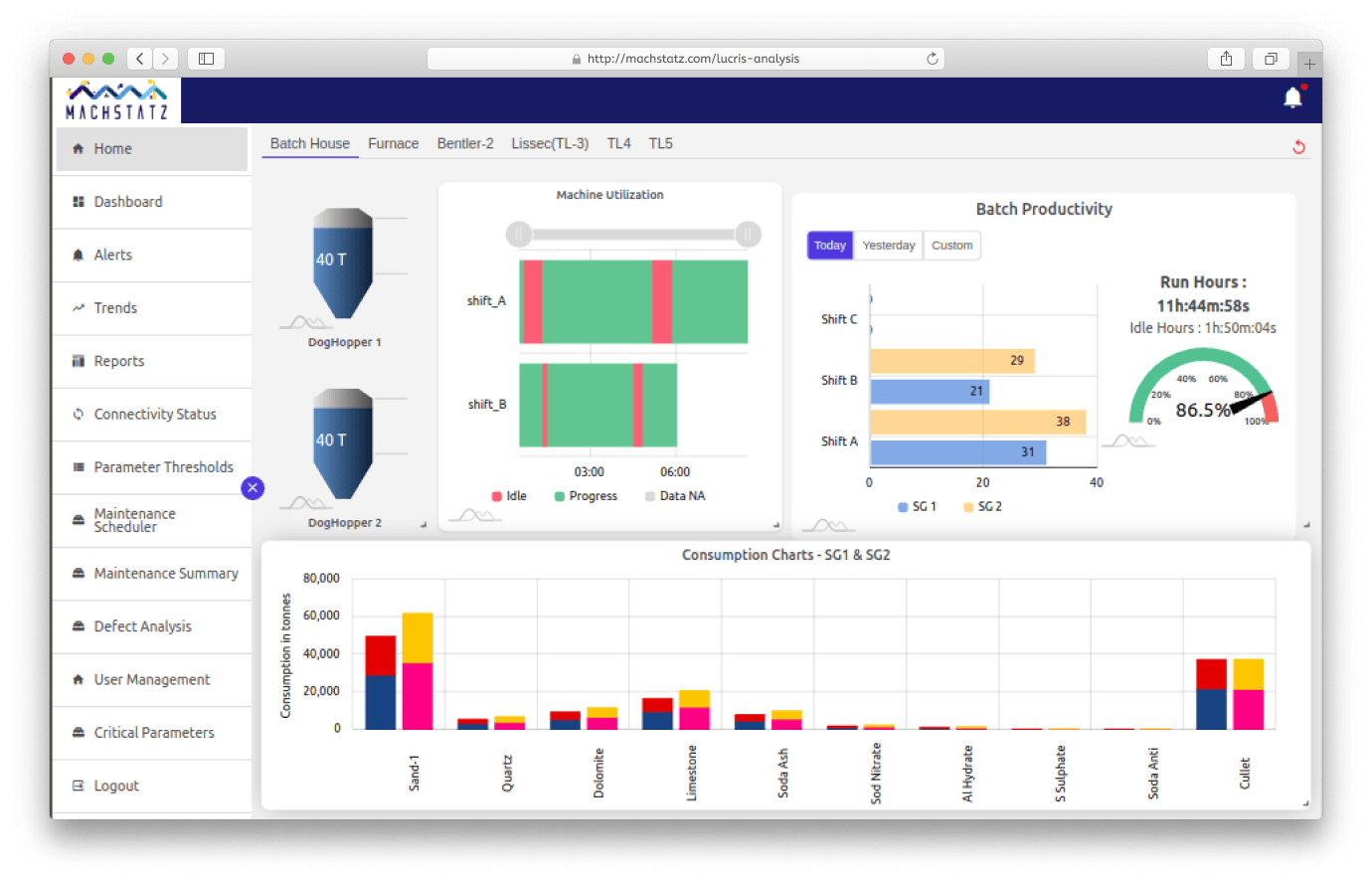

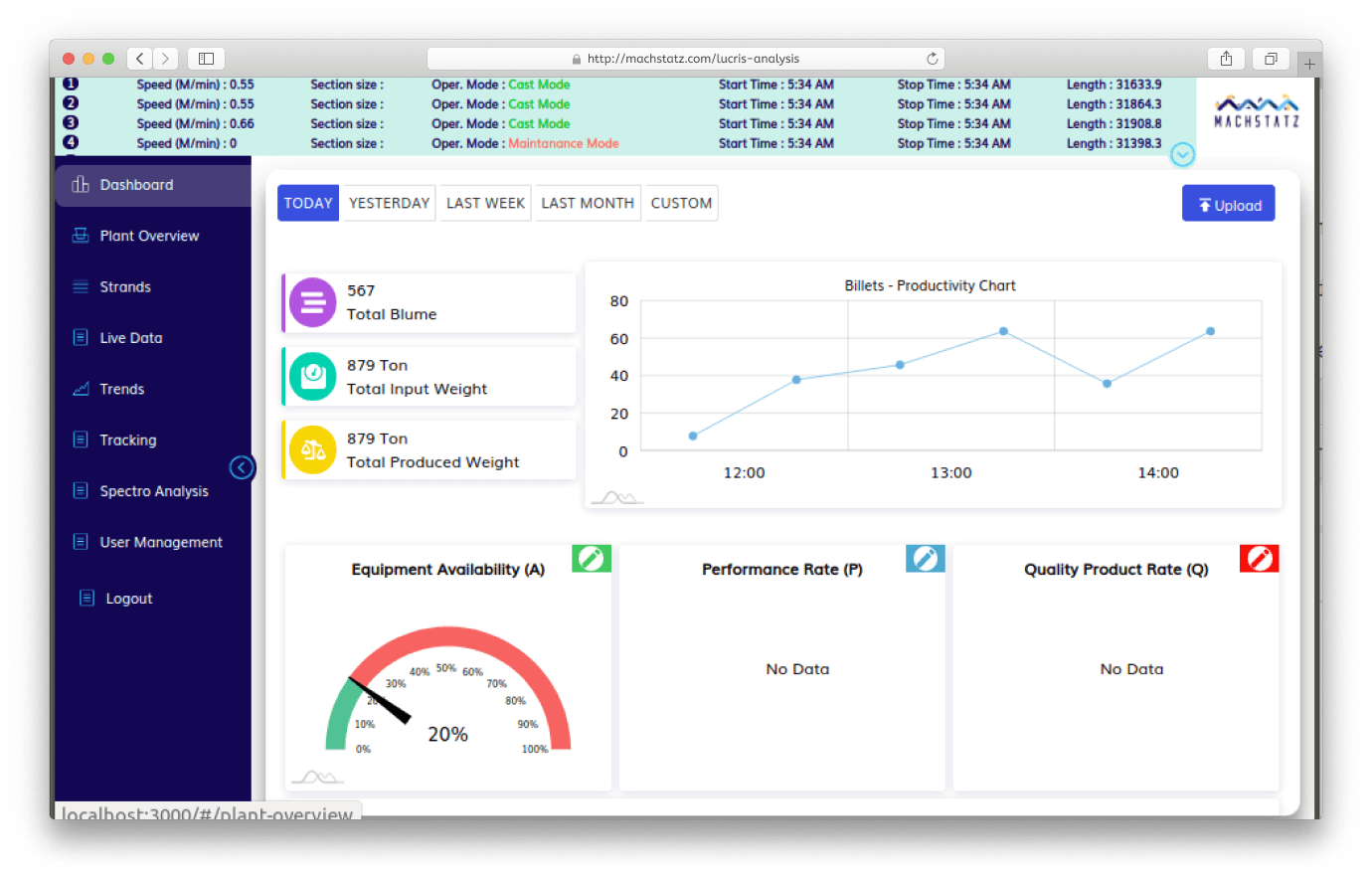

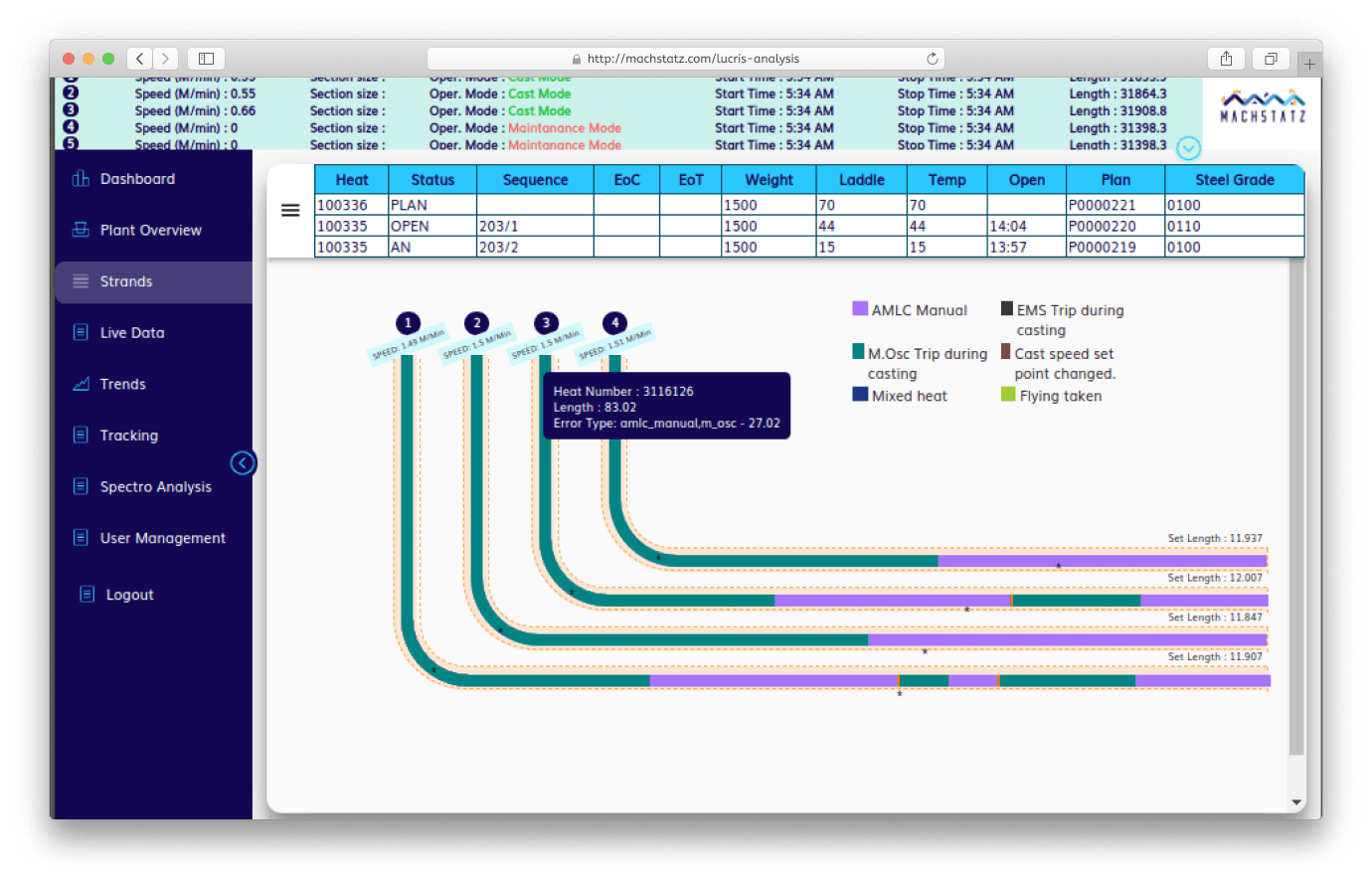

Learn moreLucrys Analytics

We built Lucrys Analytics Platform so that you can use its AI & ML modules to detect anomalies in production process, identify defects in manufactured products, ensure production and efficiency. In short, it allows you to ensure your plant runs smoothly at all times

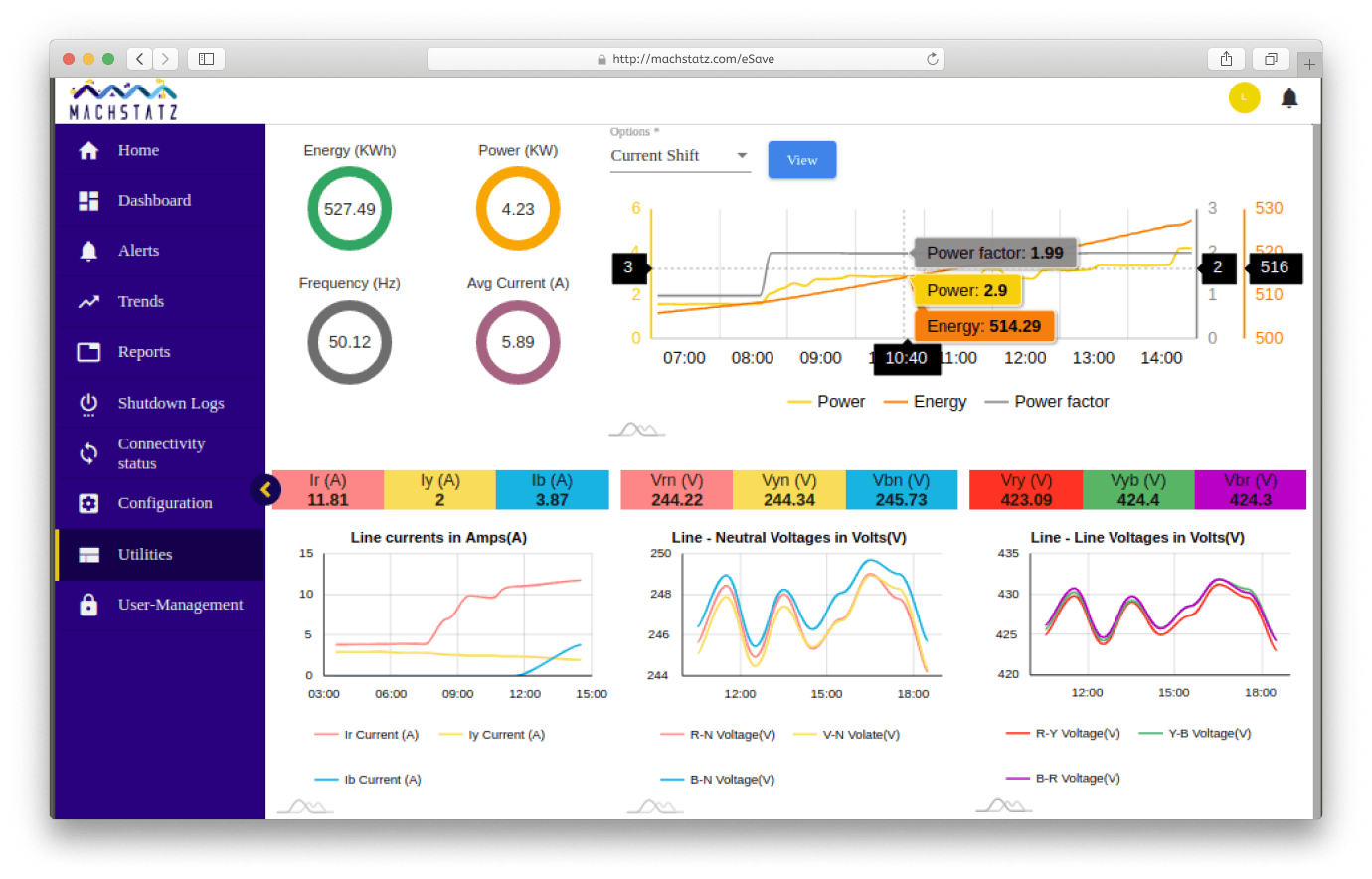

Learn moreeSave - Energy Analytics

eSave component can connect to your energy meters through RS485, RS232, MODBUS protocols. Monitor vital energy parameters from anywhere across your handheld devices. Map your day-to-day energy consumption to your costs and revenues seamlessly. The plug and play feature of this suite will help you in deploy the solutions within no time.

Learn more